STREEV

Max Boll

How can we enable people to shape their local environment in a socially and ecologically sustainable way? The STREEV system equips the user with an understanding of the product(-ion) context and produces customized, complex wood structures in 3D.

System goal

Being involved in the whole production process of an item fosters our understanding of its impact on our social and ecological environment. How can we make this impact transparent to more people? A supposedly transparent material is wood. Yet, most of the products we perceive as wood are made of industrial wood-composites like chipboards, which are created in complex socio-ecological contexts. An understandable production process most influential to the STREEV system can be found in traditional joinery and contemporary architectural wood-production.

System function

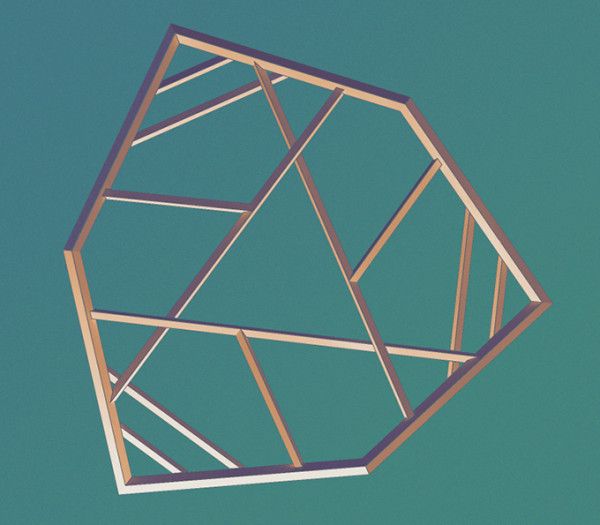

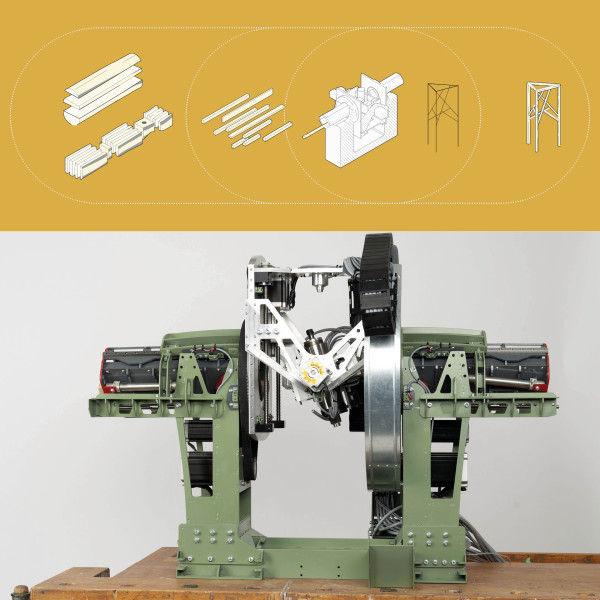

Trees grow in complex 3D structures, which need surprisingly little material to be resistant to forces like wind. Akin to these principles seen in nature, more traditional structural building techniques connect single beams and slats using wood joints, which come in many different forms. The STREEV system contains an experimental design kit, which mimics the behavior of these wood joints. Beginners get to know the features while experimenting with the design kit. More experienced users can select pre-configurations or generate structures digitally. After designing a structure, our five-axes milling machine carves the joints into the wood slats. The tools can move in almost any angle, while still being compact for a range of dimensions from 15x15 up to 70x70mm with „infinite“ length. The small size and low energy consumption (household socket) of the machine allow for a broad range of use cases such as small workshops, maker spaces and on-side-production.

Project scope

Methodologically, we aim at designing a social innovation process involving technical development. Respecting and appreciating the social role of the production process leads to the design of valuable activities and valuable products—a modest and therefore democratic objective. Technically, the variety and flexibility of geometric structures are unique features of the STREEV system, which are not to be found in projects taking an otherwise similar approach (e.g. joyn machine, studio milz). In comparison to industrial machines with similar numbers of axes, our system is not just smaller but also opens up a different scope. A third distinguishing feature is that the complex and irregular structures made out of small wood slats open up the possibility of advanced aesthetics, structural performance and material-saving design.

Projectpartner: Kay Boll